Table:

U3

Designed with a stationary work table for repeatable accuracy regardless of work piece size or weight

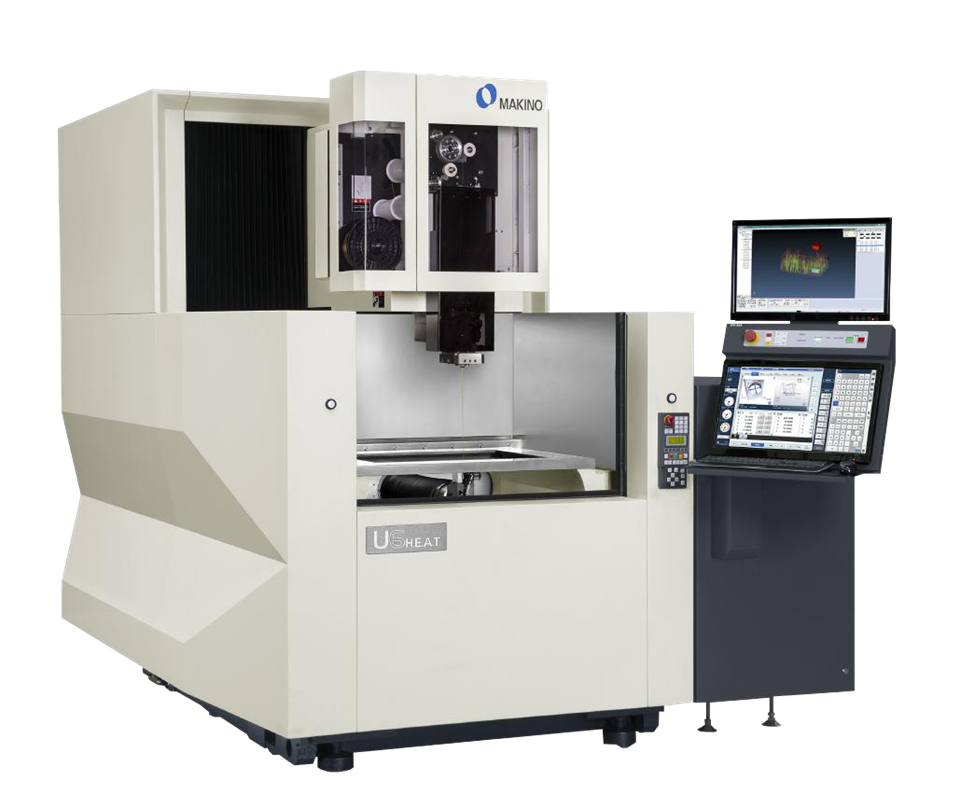

Wire EDM uses an energized wire electrode in a submerged bath of dielectric fluid to machine conductive metals, and offers an efficient manufacturing method to produce part geometry details that are difficult to machine by other methods. Makino EDMs are designed for supreme reliability and industry leading precision, and produce finer surface finishes while significantly lowering maintenance and consumables costs.

Makino EDMs stand apart with the intuitive Hyper-i control system, a streamlined and efficient interface that helps you get work done faster. A large high definition 24” touch screen functions like a smart device (phone/tablet), allowing operators of all skill levels to benefit from its inviting and familiar operation that substantially reduces training requirements. The Hyper-i control further elevates an operator’s capability with several integrated advanced functions, such as hyper-linked digital manuals and video tutorials, E-Tech Doctor, and EZ-Cut that deliver higher levels of productivity to the operator’s fingertips.

Makino offers a range of wire EDM machining solutions.

The U-Series machines are designed around features and solutions that drive production and optimal efficiency. Unique to the industry, the U-Series can be configured with a choice of wire guide systems that best support the part and process requirements. All machines feature dual independent flush pumps, turning flushing into a CNC programmable element, and the H.E.A.T. configuration provides higher flushing capacity for faster machining speeds of poor flush applications.

The Makino Ui-Series will provide an universal approach to a wide range of premium applications to adress the most demanding needs of precision stamping, job shop and medical industries.

The design enhances the unattended operation of small wire and small part detail work. With pinpoint sub-micron precision and outstanding surface finish, this oil-based dielectric horizontal wire EDM is ideal for small electronics, medical and micromachining applications.

Makino is the world leader in EDM (Electrical Discharge Machining). Makino EDM means faster processing times and superior surface finishes for even the most complex part geometries. See how Makino turns innovation and technology into increased production and a lower cost per part for our customers.

Table:

4-Sided 630 x 450 mm

X:

370 mm

Y:

270 mm

Z:

220 mm

Table:

4-Sided 630 x 450 mm

X:

370 mm

Y:

270 mm

Z:

220 mm

Table:

4-Sided 910 x 710 mm"

X:

650 mm

Y:

450 mm

Z:

420 mm

Table:

4-Sided 910 x 710 mm"

X:

650 mm

Y:

450 mm

Z:

420 mm

Table:

630 x 450 mm

X:

370 mm

Y:

270 mm

Z:

220 mm

Table:

910 x 710 mm

X:

650 mm

Y:

450 mm

Z:

420 mm

Table:

N/A Work Fixture

X:

160 mm

Y:

160 mm

Z:

50 mm